Purpose of Bitumen and Hull Blacking Paints

Bitumen and hull blacking paints are specialized coatings designed to protect the submerged sections of boats and marine structures from corrosion, abrasion, and water ingress. They provide a waterproof barrier, preventing rust and extending the lifespan of vessels, particularly those operating in inland waterways.

Main Types of Bitumen and Hull Blacking Paints

Bitumen-Based Paints

Bitumen-based paints are traditional, single-component coatings. They offer a flexible, waterproof layer suitable for steel and wooden hulls.

Advantages include

- Maintenance - Easily recoatable, allowing for straightforward touch-ups and maintenance.

- Cost-Effective - Generally more affordable than epoxy alternatives.

- Ease of Application - Can be applied without specialised equipment.

Some limitations include

- Durability - Typically requires reapplication every 2-3 years.

- Compatibility – Should not be applied over existing epoxy coatings without proper surface preparation.

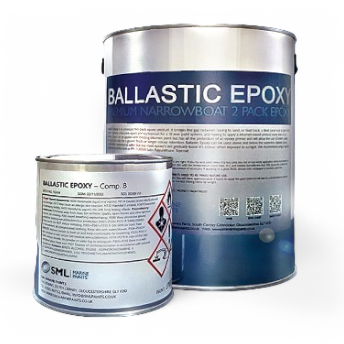

Two-Pack Epoxy-Based Paints

Two-pack epoxy paints consist of a resin and hardener that, when mixed, form a tough, chemically cured coating. Products like Ballastic Epoxy are designed for steel boats, offering superior corrosion resistance and adhesion.

Advantages include

- Provides excellent adhesion to steel substrates and offers a durable, glossy finish resistant to chemicals and abrasion.

- Longevity - Can provide protection for up to 10 years with correct preparation and application

- Durability - More resistant to mechanical damage and environmental factors.

Some limitations include

- Application Complexity - Requires thorough surface preparation and mixing before application.

- Cost - Higher initial investment compared to bitumen paints.

Key Considerations When Selecting Bitumen and Hull Blacking Coatings

Choosing the right marine paint depends on various factors:

- Vessel Usage - for inland waterways, bitumen-based paints like SML Ballastic Black are suitable. For vessels exposed to harsher coastal conditions, two-pack epoxy paints offer enhanced protection.

- Existing Coatings - Ensure compatibility; epoxy paints should not be applied over bitumen without appropriate preparation.

- Maintenance Schedule - Consider the desired maintenance intervals; epoxy coatings require less frequent reapplication.

- Budget - Balance between upfront costs and long-term durability.

Key Steps in Applying Bitumen and Hull Blacking Paint

Below you will find a general overview of the steps to be considered when applying bitumen and hull blacking paint. You should always refer to the specific data sheets and guides that you can find on each of our product pages for more detailed information.

Step 1 - Surface Preparation

- Cleaning - Remove all dirt, grease, and marine growth from the hull.

- Rust Removal - Use wire brushing or sandblasting to remove rust and loose material.

- If applying epoxy hull blacking over existing single pack paint, this should be rubbed back as far as possible to bare metal.

- Drying - Ensure the surface is completely dry and dust freebefore application.

Step 2 – Mixing and Thinning

- Bitumen Paints - Stir thoroughly. SML Alkyd Thinner may be used if required but when painting in cold conditions it is better to warm the paint to room temperature to reduce its viscosity than to reduce viscosity by thinning

- Epoxy Paints - Mix the resin and hardener as per our application guides until they become homogenous. Epoxy Thinners may be used up to 10% if required for optimum airless spray application

Step 3 - Application

- Avoid painting when substrate temperatures are below 5°C and above 30°C particularly when using single pack bitument paint. Be aware that the substrate temperature may be a lot higher than the ambient temperature, particularly in direct sunlight.

- Ensure good ventilation in confined areas.

- Apply with airless spray or brush and roller. Apply multiple coats as required, allowing adequate drying time between layers.

- It is recommended to have a brush to hand for the first coat to help allow the working of paint into pitted areas. Rollers tend to skate over the surface

Step 4 - Drying and Curing

- Bitumen Paints - Typically touch-dry within hours. Refer to the data sheet for pvercoating times

- Epoxy Paints - Refer to data sheet/application guide for details of overcoating and curing times.

Step 5 - Inspection

- Coverage Check - Ensure uniform application. Pay particular attention to pitted areas – make sure these are covered when painting subsequent coats.

- Thickness Verification - Use a wet film thickness gauge to confirm adequate film build.

Step 6 – Clean Up

Step 7 - Maintenance

- Regular Inspections - Check for signs of wear or damage annually.

- Touch-Ups - Address any areas of concern promptly to maintain protection.

Frequently Asked Questions (FAQs)

The FAQ's below are for general guidance only. For specific questions, please refer to the application guides on our product pages or give us call and we will answer any questions that you have.

Q. Can I apply epoxy paint over existing bitumen coatings?

A. Yes, provided that the existing coating is well rubbed back and its overall thickness does not exceed 100 microns. Epoxy coatings (which are hard and relatively inflexible) tend to crack off thick (relatively soft and flexible) single pack bitumen coatings. If switching from bitumen to epoxy, to ensure durability, it is best to strip back to bare metal as much as possible before applying an epoxy primer.

Q. What is the drying time for bitumen paint?

A. Bitumen hull blacking is touch-dry in approximately 3-6 hours, depending on weather conditions. It is advisable to wait 48 hours before relaunching the boat

Q. Are bitumen paints suitable for saltwater environments?

A. Bitumen paints are primarily designed for freshwater use, such as canals and rivers. They offer good waterproofing but lack the long-term durability for saltwater exposure. Epoxy-based coatings can be used in saltwater environments.

Q. Can I apply hull blacking paint myself?

A. Yes, both bitumen and epoxy hull blacking paints can be applied as DIY projects. However, proper surface preparation and correct application techniques are necessary to ensure durability.

Q. How do I prepare the hull before painting?

A. Proper surface preparation is crucial for good adhesion. The hull should be thoroughly cleaned to remove dirt, grease, and marine growth. Rust and loose material should be removed. The surface must be completely dry before application.

Q. How many coats of hull blacking paint should I apply?

A. For bitumen paints, at least two coats are recommended for adequate protection, with additional coats providing enhanced durability. For epoxy coatings, the required thickness depends on manufacturer specifications, but two or more coats are typically needed.

Q. How long will epoxy hull blacking last compared to bitumen?

A. Epoxy coatings can last up to 10 years with proper application and maintenance, whereas bitumen-based coatings generally require recoating every 2-3 years. The longevity of epoxy paints makes them more cost-effective in the long run.

Q. Can I apply bitumen or epoxy hull blacking in cold or damp conditions?

A. Application should be done in dry weather with temperatures above 5°C (41°F). Lower temperatures will slow drying and curing times

Q. Can I apply a topcoat over hull blacking for extra protection?

A. Bitumen paints should not be overcoated with standard topcoats, as they may not adhere well. It is a good idea to apply a topcoat over epoxy coatings to give additional UV protection.

Q. Can hull blacking prevent rust formation?

A. Yes, both bitumen and epoxy hull coatings create a waterproof barrier that helps prevent rust. However, if rust is already present, it must be removed before painting to ensure the best results.

Q. How do I know when my hull needs repainting?

A. Signs that your hull needs recoating include visible rust and flaking or peeling paint. By selecting the right hull blacking paint and following best application and maintenance practices, you can ensure long-lasting protection for your vessel.

Loading Products...

Loading Products...